CTA

Chahe Slipper Ho Ya Sneaker — Machine Yahan Milegi!

Whether you’re starting a new Shoe brand or upgrading your existing factory, we’re here to guide you with the right shoe-making machines. Fill out the form below, and our team will get in touch within 24 hours.

About Us

Pioneering Shoe Making Machines in India Since 1984

At BSM India, we don’t just build machines — we build the backbone of India’s footwear industry. With over 40 years of expertise in manufacturing and supplying Shoe-Making Machine, we’ve helped thousands of businesses, from small startups to large-scale export houses, build reliable, efficient, and profitable production systems.

What started in 1984 as a small service and trading operation has grown into a trusted, innovation-driven company with 400+ machine models, 40,000+ satisfied customers, and a pan-India service network.

- Hydraulic Cutting Presses

- Sole Attaching Machines

- Toe & Heel Lasting Machines

- Skiving, Stitching & Finishing Lines

- Shoe Automation Systems

CTA

Why Leading Shoe Brands Trust BSM India

When it comes to choosing reliable Shoe-Making Machine, thousands of manufacturers across India turn to BSM India for one simple reason: We build machines that build businesses. From first-time entrepreneurs to large-scale exporters, BSM is known for delivering not just hardware — but complete, high-performing production ecosystems that scale with your needs.

Over a Decade of Manufacturing Excellence

- Decade-long experience in design, mechanics, and automation

- Machines developed through customer insight, not guesswork

- Trusted by brands producing sports shoes, safety footwear, leather shoes, and more

400+ Active Units Across India & Beyond

- Units deployed in Agra, Kanpur, Kolkata, Delhi, Bahadurgarh, Mumbai, Chennai, and more

- Strong base in manufacturing clusters and private-label factories

- We serve both urban centers and emerging industrial zones

Engineered for Indian Factories — Not Just Showrooms

- Designed to handle leather, EVA, PU, PVC, TPR, canvas, and more

- Operator-friendly controls with low learning curve

- Optimized for Indian footwear materials, climate, and workflow realities

Nationwide Support, Real Human Help

- On-site installation and hands-on operator training

- Preventive maintenance and breakdown response services

- Readily available spares, direct WhatsApp support, and toll-free helpline

- Service engineers deployed across zones for faster turnarounds

Products

Industries We Serve

Footwear Industry

From sports shoes to leather boots and EVA sandals, BSM India delivers reliable footwear machinery solutions. Our advanced shoe making machines—from toe-lasting to hydraulic cutting—are built for precision, speed, and durability.

We provide scalable equipment for cutting, pressing, stitching, and finishing, designed to work with leather, EVA, and synthetic materials. Whether starting a new line or expanding production, our shoe making machines ensure consistent quality and efficiency for every step of footwear manufacturing.

Garments & Apparel

From fashion wear to workwear and uniforms, BSM India delivers reliable garment machinery solutions. Our advanced machines—from fabric cutting to sewing and finishing—are engineered for precision, speed, and long-lasting performance.

We provide scalable equipment for stitching, hemming, printing, and pressing, designed to work with cotton, polyester, denim, and blended fabrics. Whether launching a new clothing line or expanding operations, our machines ensure consistent quality and efficiency for every step of apparel manufacturing.

Bags & Belt Manufacturing

From stylish handbags to rugged leather belts, BSM India offers dependable machinery for the bag and belt manufacturing industry. Our advanced machines—covering cutting, embossing, stitching, and finishing—are built for accuracy, durability, and high productivity.

We provide scalable equipment to handle leather, PU, canvas, and synthetic materials, ensuring precise shaping, secure stitching, and flawless finishing. Whether starting small-scale production or upgrading to high-volume output, our solutions deliver consistent quality and efficiency.

Furniture & Upholstery

From elegant sofas to ergonomic chairs, BSM India supplies trusted machinery for furniture and upholstery production. Our advanced machines—from fabric cutting to foam gluing and finishing—are designed for precision, durability, and high efficiency.

We offer scalable solutions for leather, fabric, and synthetic upholstery, ensuring neat stitching, smooth finishing, and long-lasting quality. Whether for small workshops or large-scale factories, our equipment meets the demands of both style and strength.

Packaging Industry

From corrugated boxes to premium gift packaging, BSM India delivers reliable machinery for the packaging sector. Our advanced machines—from cutting and folding to gluing and embossing—are designed for speed, precision, and consistent results.

We provide scalable solutions for paper, cardboard, and flexible packaging materials, ensuring perfect shapes, strong seals, and attractive finishes. Whether producing bulk industrial packaging or custom designs, our machines enhance efficiency and quality.

Automobile Sector

From car interiors to safety accessories, BSM India provides high-performance machinery for the automobile sector. Our advanced machines—covering cutting, stitching, and forming—are built for accuracy, reliability, and consistent output.

We offer scalable solutions for leather, fabric, rubber, and synthetic materials, ensuring durability and precision in every component. Whether for small custom shops or large manufacturing units, our equipment meets the highest industry standards.

Stationery Industry

From notebooks to premium diaries, BSM India offers dependable machinery for stationery manufacturing. Our advanced machines—from cutting and binding to printing and finishing—are designed for accuracy, speed, and durability.

We provide scalable equipment for paper, cardboard, and synthetic covers, ensuring neat binding, sharp cuts, and quality finishes. Whether producing mass-market stationery or premium custom products, our solutions deliver consistent results every time.

Orthopedics

From orthopedic footwear to custom braces, BSM India supplies precision machinery for the orthopedic manufacturing industry. Our advanced machines—covering cutting, molding, and finishing—are engineered for accuracy, durability, and patient comfort.

We provide scalable solutions for leather, EVA, and specialized orthopedic materials, ensuring proper shaping, secure assembly, and smooth finishing. Whether for specialized clinics or large-scale production, our equipment ensures quality and reliability.

Gloves Manufacturing

From industrial safety gloves to premium leather wear, BSM India delivers trusted machinery for glove manufacturing. Our advanced machines—from cutting and shaping to stitching and embossing—are built for precision, durability, and efficiency.

We provide scalable solutions for leather, fabric, and synthetic materials, ensuring comfortable fit, strong seams, and premium finishing. Whether producing in bulk or creating custom designs, our machines guarantee consistent quality at every stage.

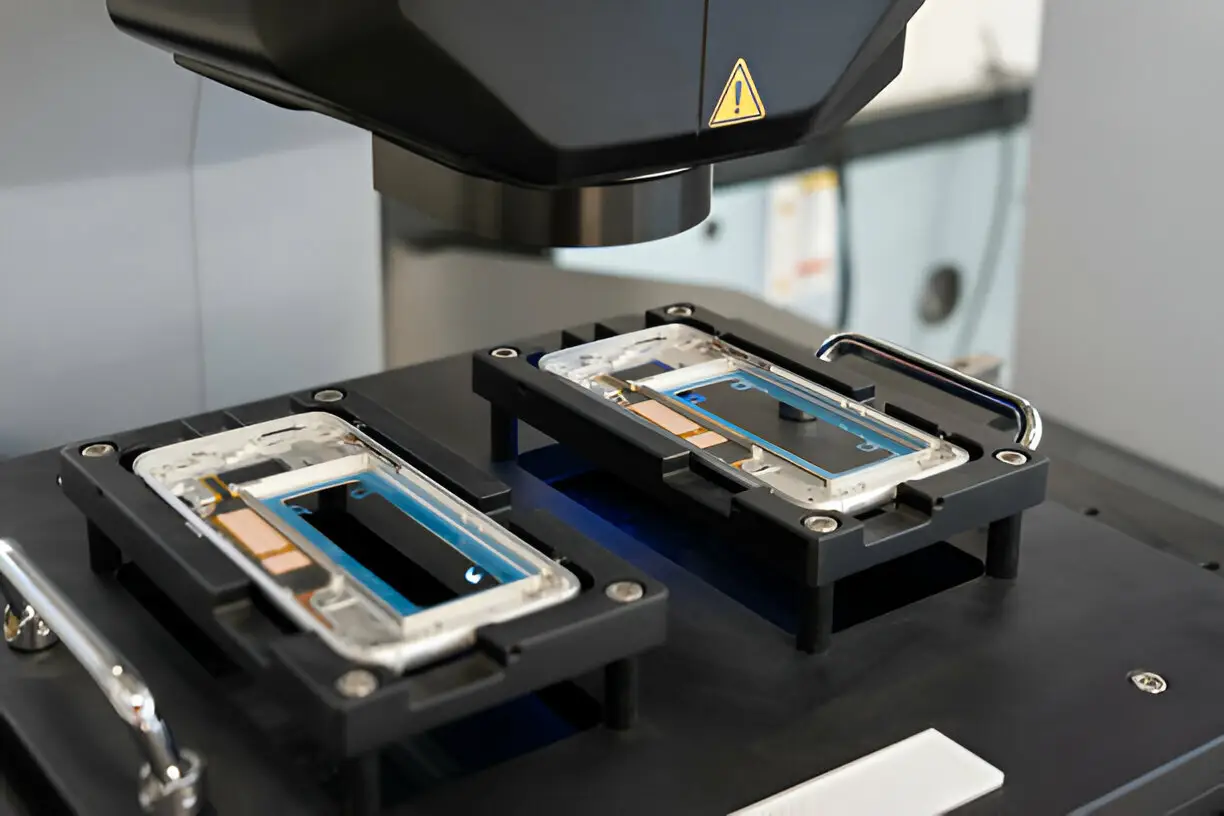

Phone Case Production

From sleek plastic cases to premium leather covers, BSM India offers reliable machinery for phone case production. Our advanced machines—covering cutting, molding, printing, and finishing—are designed for speed, accuracy, and high-quality output.

We provide scalable solutions for leather, PU, silicone, and hard plastic materials, ensuring precise fit, strong structure, and attractive design. Whether for mass production or specialized custom orders, our equipment delivers consistent results every time.

Brands

Brands We Work With

Our Happy Customers Say About

Rakesh Kumar

Pooja Verma

Nitesh Sharma

Rajeev Bansal

Recent Blogs

Frequently Asked Questions

What is a shoe making machine and how does it work?

A shoe making machine is an industrial device designed to automate key stages in the footwear manufacturing process—such as cutting, stitching, lasting, and sole attaching. Each machine is dedicated to a specific task and helps improve production speed, accuracy, and quality. By replacing manual labor with precision technology, these machines increase consistency and reduce material wastage.

Which shoe making machines do I need to start a footwear business?

The machinery required depends on your footwear type (e.g., sports shoes, leather shoes, EVA slippers). A standard setup for small businesses includes:

- Hydraulic cutting press

- Upper stitching machine

- Toe and heel lasting machine

- Sole attaching machine

You can also add finishing and trimming units for higher-quality results. Our team will help you customize a shoe making machine setup tailored to your production goals and budget.

Can I start small with just one or two machines?

Absolutely. Many entrepreneurs begin with a single shoe making machine—usually a stitching or cutting machine—and scale over time. We support phased setups where you can gradually add more machines as your business grows.

What types of shoes can I produce with these machines?

Our machines are versatile and support manufacturing of:

- Sneakers and sports shoes

- Formal leather shoes

- Sandals and slippers

- Safety shoes and industrial footwear

- Flip flops, boots, and fashion shoes

Each shoe making machine model can be configured for different materials like EVA, leather, PVC, PU, and rubber.

Do I need prior technical knowledge to operate a shoe making machine?

No prior experience is required. Our machines are user-friendly, and we provide comprehensive training after installation. We also offer video tutorials, manuals, and live support to guide new operators through the setup and usage.

Is training included with machine purchase?

Yes. We offer:

- On-site machine training (if required)

- Online demo via WhatsApp or Zoom

- Lifetime technical assistance by phone or video

- Access to how-to videos for all our shoe making machines

How much space is needed for a small-scale footwear unit?

A micro unit can be set up in just 300–500 sq. ft., depending on the scale and number of machines. We provide full factory layout guidance for startups and growing businesses.

Can these machines handle all shoe sizes and styles?

Yes. Our shoe-making machines are built with adjustable settings to handle men’s, women’s, and children’s footwear. Whether you’re making long boots or school shoes, our machines adapt to your design needs.

What are the power and electricity requirements?

Most industrial machines require a 3-phase connection (2–5 HP), while some compact models are available in single-phase for use in home-based or workshop setups.

How many shoes can I make per day with these machines?

Depending on the machine type, material, and workforce:

- Small units: 300–500 pairs/day

- Medium units: 800–1200 pairs/day

- Large-scale factories: Up to 2000+ pairs/day

Our high-speed shoe making machines are engineered to deliver volume with minimal error.

Are the machines made in India or imported?

We offer both Made-in-India and internationally imported machines. All machines—whether domestic or imported—are rigorously tested to meet Indian factory conditions and come with spare part support.

Do you offer EMI or financing options?

Yes. Through partnerships with financial institutions, we offer:

- Business loans

- EMI-based purchasing

- Subsidy guidance (if available under government schemes)

Get started with low upfront investment and pay as you grow.

Do you offer service and delivery in my city?

We supply and support shoe making machines across India, including major hubs like:

- Delhi NCR

- Kanpur

- Agra

- Kolkata

- Chennai

- Mumbai

- Hyderabad

- Bangalore

- Jaipur

- Pune

- Ahmedabad

And over 40+ cities via our authorized dealer and technician network.

Do your machines come with warranty and spare parts?

Yes. All machines come with a minimum 1-year warranty and lifetime tech support. We also provide:

- AMC (Annual Maintenance Contract)

- Local spare parts availability

Branded components (Yuken, L&T, Schneider, etc.)

How can I place an order for a shoe making machine?

Simple! You can:

- Fill out the contact form on our website

- Tap the WhatsApp button for quick chat

- Call us directly for consultation

Once we know your footwear type, production goal, and city, we’ll share a tailored quote and factory setup plan.

Ready to Launch Your Shoe Brand?

Whether you’re planning to make sneakers, leather shoes, sandals, or flip flops — we’re here to help you set up your own mini factory with the right shoe making machines.

From machine selection to layout design and training — we guide you through every step!